Efficient and Secure Tanker Management: A Growing Necessity in Qatar

The smooth operation of sewage treatment plants hinges on the effective management of tanker traffic. Ensuring a steady inflow and outflow of tankers while maintaining robust security measures is paramount. However, traditional methods of tanker verification often relied on manual processes, leading to potential inaccuracies and inefficiencies. These inefficiencies could result in:

- Security Breaches: Inaccurate verification processes could allow unauthorized vehicles to enter the facility, compromising safety and potentially causing environmental damage.

- Traffic Congestion: Manual verification slowed down the entry and exit of tankers, leading to congestion and delays within the facility.

- Operational Bottlenecks: Manual verification processes required more manpower, reducing overall operational efficiency.

Challenge Faced by Doha West Sewage Treatment Plant

The Doha West Sewage Treatment Plant in Qatar encountered significant challenges in managing tanker inflow. These challenges mirrored the broader industry issues mentioned above:

- Inaccurate Verification: Manual verification processes were susceptible to human error, leading to the potential entry of unauthorized vehicles.

- Security Concerns: The lack of a robust verification system increased the risk of unauthorized access attempts, posing a security threat to the facility.

- Traffic Congestion: Inefficient traffic flow within the facility resulted in congestion and delays for tankers.

These challenges not only compromised security but also hampered operational efficiency at the Doha West Sewage Treatment Plant.

A Modern Solution: The Tanker Access Management System (TAMS)

To address these challenges, Traffic Tech Gulf (TTG) implemented a state-of-the-art Tanker Access Management System (TAMS) featuring Adaptive Recognition’s industry-leading Vidar Smart HDx ANPR (Automatic Number Plate Recognition) cameras. The TAMS system integrates seamlessly with existing infrastructure streamlines vehicle verification, enhances security measures, and optimizes traffic flow within the Doha West Sewage Treatment Plant.

The Core of TAMS: Technology Working in Harmony

The TAMS is a comprehensive system encompassing advanced hardware and software components. These components include:

- Adaptive Recognition’s Vidar Smart HDx Cameras: These advanced ANPR/LPR cameras capture license plates for both incoming and exiting tankers, with the highest accuracy, even in low-light conditions.

- RFID Readers: These readers provide an additional layer of verification for authorized tankers. Authorized tankers possess pre-registered RFID tags, which the readers identify upon entry and exit. This combined approach significantly reduces the risk of unauthorized access and ensures the accurate identification of all tankers utilizing the facility.

- Induction Loop Detectors: These detectors trigger ANPR cameras when vehicles are in position, ensuring accurate plate capture.

- Traffic Lights and Arm Barriers: These components regulate traffic flow within the facility, promoting safety and security. Authorized vehicles receive seamless access, while unauthorized vehicles are flagged for intervention.

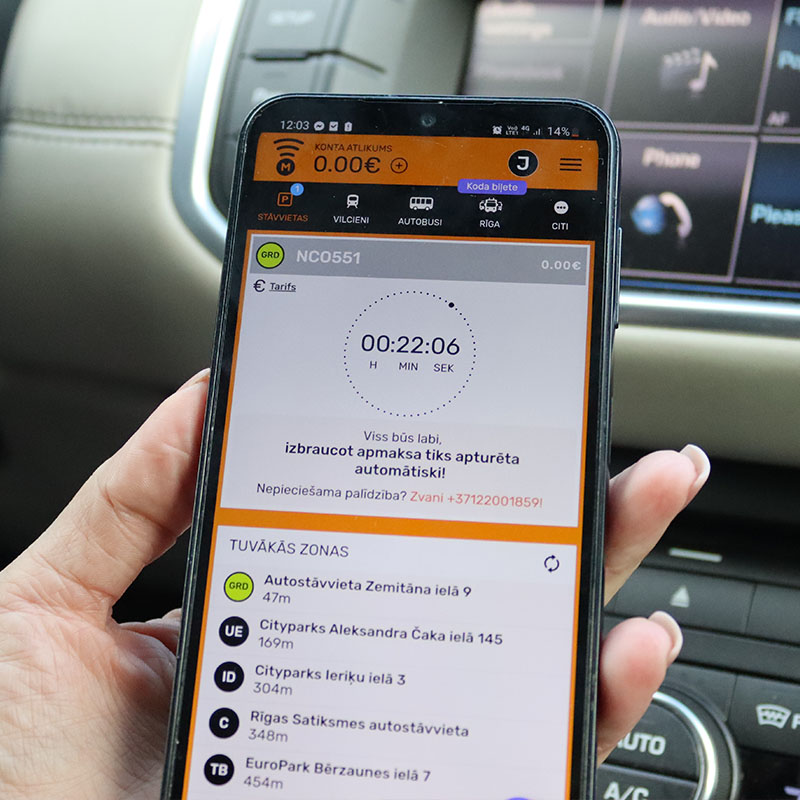

- Management Software: This software offers a central platform for real-time monitoring of the entire system. It provides operators with a clear overview of vehicle activity, facilitates data analysis, and enables system control functions like regular project management dashboards.

Significant Benefits Delivered

The implementation of the TAMS system has delivered significant benefits to the Doha West Sewage Treatment Plant, including:

- Enhanced Security: Dual verification with Vidar Smart HDx ANPR cameras and RFID readers ensures accurate identification of authorized tankers and deters unauthorized access attempts.

- Efficient Traffic Management: Real-time monitoring and traffic light control optimize vehicle flow, reducing congestion and wait times for tankers.

- Streamlined Operations: Automation of vehicle verification and bay allocation minimizes manual intervention, leading to more efficient operations and reduced manpower requirements.

- Scalability and Flexibility: The TAMS’ distributed design allows for easy expansion and integration of additional components to meet future requirements, such as integrating with weighbridge systems.

Conclusion: A Model for Modernized Tanker Management

The Doha West Sewage Treatment Plant’s implementation of the TAMS system serves as a pioneering example of how advanced technology can revolutionize essential operations. By leveraging Adaptive Recognition’s Vidar Smart HDx long-range LPR cameras at its core, the TAMS has not only addressed the facility’s immediate challenges but also paved the way for a more secure, efficient, and scalable future.

The success of this project extends beyond the immediate benefits for Doha West. It sets a precedent for other sewage treatment plants seeking to modernize their tanker management practices. The TAMS’ modular design allows for adaptation to specific needs, making it a valuable tool for facilities of all sizes. The Doha West Sewage Treatment Plant’s adoption of the TAMS demonstrates the transformative power of technology and positions them as leaders in the industry.